Making the Grade

Updates at Bowater Inc.'s newsprint plant at Grenada, Miss., have strengthened workers' protection against arc flash while easing heat stress concerns.

- By Mike Longman

- Jul 01, 2007

IN 2005, Bowater Inc., a leading producer

of coated and specialty papers and

newsprint, stood by its commitment to

ensure the safety of its workers at a

Grenada, Miss. facility that is Mississippi’s

only newsprint manufacturer. Bowater

looked to our Electrical Services and Systems

district office in Pelham, Ala. to

implement its arc flash training, perform an

Arc Flash Hazard Analysis to assess its

safety needs and concerns, and to coordinate

its power systems.

IN 2005, Bowater Inc., a leading producer

of coated and specialty papers and

newsprint, stood by its commitment to

ensure the safety of its workers at a

Grenada, Miss. facility that is Mississippi’s

only newsprint manufacturer. Bowater

looked to our Electrical Services and Systems

district office in Pelham, Ala. to

implement its arc flash training, perform an

Arc Flash Hazard Analysis to assess its

safety needs and concerns, and to coordinate

its power systems.

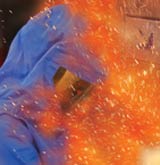

An arc flash is produced by a flow of

electrical current through ionized air after

an initial flashover or short circuit. An arc

flash event releases a tremendous amount

of energy in the form of thermal heat, toxic

fumes, pressure waves, blinding light,

sound waves, and explosions that can result

in serious injuries that include critical

burns, collapsed lungs, loss of vision,

ruptured eardrums, and puncture

wounds. Some are fatal.

Accidents, unintentional contact

with electrical systems,

equipment failure, improperly

designed equipment, and/or

work procedures can cause an arc

flash explosion. According to the

National Fire Protection Association,

an arc flash occurs “when

an electric current passes through

air between ungrounded conductors

or between ungrounded conductors and

grounded conductors.” NFPA 70E, Standard

for Electrical Safety in the Workplace,

sets forth basic requirements for electrical

safety at work sites and requirements for arc

flash hazards, in particular.

BOWATER’S NAME

CHANGING, TOO

Bowater is merging with Abitibi-Consolidated

Inc., another large newsprint

supplier, in what the companies call a

“merger of equals.” The resulting company,

AbitibiBowater, will be the third largest

public paper and forest products

company in the United States and the

eighth largest in the world.

The company’s headquarters and

executive offices will be located in Montreal,

Canada. U.S. regiona manufacturing

and sales offices will be in

Greenville, S.C. |

An arc flash releases dangerous levels of

radiant heat energy that can cause fatal or

severe burns. Fatal burns can occur to

workers up to 5 feet or more from the arc,

and severe burns can happen up to 10 feet

away during a high-energy arc flash. An arc

flash produces some of the highest temperatures

on earth—up to 35,000 degrees

Fahrenheit. These excessive temperatures

cause the air and metal in the path of the arc

to expand and explode, creating an arc blast.

Protective Clothing Strikes a Balance

Based upon the initial systems study findings,

Bowater and our team devised a

strategy to reduce arc flash danger significantly

at the Grenada facility. Bowater

immediately called upon our power systems

expertise to coordinate its existing electrical

protective measures, devices, and monitoring,

as well as conduct the arc flash

analysis. An integrated systems approach for

Bowater served to identify potential arc flash

hazard areas within the electrical system and

offer a variety of possible solutions.

Employee safety was the primary concern

of Gary Fant, Bowater’s maintenance

manager. Because of generally hot and

humid conditions at the facility, Fant

wanted to create an environment in which

the employees could wear sufficient personal

protective clothing to prevent the

potentially fatal or severe effects of arc

flash, yet not so much that employees

would be exposed to the danger of

extreme heat stress.

Installation of new switch units offered

the primary line of defense. These innovative

protective devices, installed in the

company’s power circuit breakers, lower

arc flash incident energy levels by temporarily

lowering trip settings while

workers are performing work on the energized

electrical system.

Bowater’s commitment to employee

safety and arc flash incident prevention

was emblematic of its historical efforts to

prevent workplace accidents. The company’s meticulous recordkeeping and data

collection removed a major hurdle faced

with many industrial clients; implementation

could be expedited because Bowater

had helped lay the groundwork. Still, there

were several key challenges during the

safety solutions implementation.

No Downtime Allowed

Bowater, one of the world’s largest

newsprint producers, could not afford

lengthy downtime. This led to a tight timeframe

to upgrade and install the units onto

the company’s circuit breakers. Bowater’s

production schedule allowed only a threeday

window for operation shutdown,

during which the retrofitting and testing of

96 circuit breakers in almost 30 locations

had to take place, while simultaneously

performing testing and maintenance at all

levels of the power system.

Several workstations were set up to

retrofit the units onto the circuit breakers

and test them. Switchgear specialists were

brought in from Alabama and Louisiana to

oversee the project. In the meantime, additional,

specific information was being collected

about the connected loads and operating

parameters for each breaker, and an

on-site system study was under way to

verify proper settings for each individual

breaker. While the installation took place,

key parts of the Bowater mill remained

open and functional so other necessary

maintenance work could be done.

The work was completed in June 2006,

resulting in a state-of-the-art safety system

and maximum peace of mind for electrical

maintenance employees and managers.

Heat Stress Concerns Eased

By installing the units, Bowater was able to

offer its electrical workers three key safetyand

reliability-related benefits:

1. The change lowered arc flash incident

energy levels in work locations.

2. Less arc flash PPE is required, which

reduces heat stress. For example, MCC 51-

05 before the retrofit was a category 3 arc

flash hazard at 8.3 cal/cm2, requiring a

flame resistant (FR) shirt and pants, plus

FR coveralls over them. After the retrofit,

MCC 51-05 was reduced to a category 1

arc flash hazard at 1.9 cal/cm2, requiring

only an FR shirt and pants.

3. For system reliability, replacing the

older analog breaker trip units with microprocessor-

based true RMS trip units gives

more flexibility to the power systems engineer

in making settings for system coordination.

Also, the true RMS units are less

susceptible to nuisance tripping from harmonic

signals on the line generated by

Bowater’s paper mill drives.

Bowater is currently implementing an

electrical safety program that includes all

aspects of NFPA 70E. It is implementing

procedures to take the arc flash safety

improvements within its electrical system a

step beyond. As the company develops and

implements its ongoing electrical safety

program, informational sharing sessions

will increase employees’ awareness of their

evolving role in the overall safety program.

With a safety initiative of this magnitude,

there is no downtime.

This article originally appeared in the July 2007 issue of Occupational Health & Safety.