Four Steps to Protection

We have Frank run the machine during the morning hours and Jim run it in the afternoon. We have not cut down the noise of the machine, but we've cut their noise exposures in half.

There you are, the operator of this big machine that produces a lot of heat, smoke, noise, and vibration. You have to turn it on and off and periodically take gage readings. The question is, to what are you exposed? (I’ll wait while you get paper and pencil so you can write down the answers.)

The answer, of course, is heat, smoke, noise, and vibration. What we need to do is to protect you from all of those hazards -- hazards that are similar to what your employees may be exposed to all of the time.

The answer, of course, is heat, smoke, noise, and vibration. What we need to do is to protect you from all of those hazards -- hazards that are similar to what your employees may be exposed to all of the time.

The Question

What's the best way to protect your employees? Hmm, what's that you say? Give them PPE? Have I heard you correctly? Let's see a show of hands -- how many of you agree that using PPE is the best way to protect your employees? Don't be shy, get those hands up.

Wow! Only a few of you have your hand up. That's interesting. What we need to do is figure out how to best protect our employees.

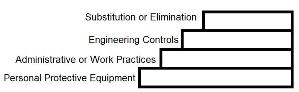

The Hierarchy of Controls

The hierarchy of controls is the various actions that are taken to protect employees when they have to work either with hazardous chemicals or in a hazardous environment. For a definition, see: http://en.wikipedia.org/wiki/Hierarchy_of_hazard_control.

OSHA requires the use of hierarchy of controls in several areas of its regulations and in several letters of interpretation (e.g., 1910.1000(e), VPP application instructions).

These are the "Four Steps to Protection":

Step One: If we are able to either substitute a less-hazardous material for the hazardous one or eliminate it altogether, we have eliminated the hazard. For example, rather than using a flammable solvent to clean our part, what about using soap and water to clean the part and then air drying it?

Step One: If we are able to either substitute a less-hazardous material for the hazardous one or eliminate it altogether, we have eliminated the hazard. For example, rather than using a flammable solvent to clean our part, what about using soap and water to clean the part and then air drying it?

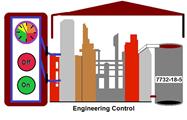

Step Two: At this step, we still have the hazard because we weren’t able to substitute anything or eliminate it, but now we want to see whether we can engineer out the hazard. Do you remember our big, huge machine that makes a lot of heat, smoke, noise, and vibration? We need to protect the operator from all of that and we can do that by using engineering controls.

We have isolated the controls by moving them exterior to the machine and by putting a hood over the top to collect the heat and smoke. The operator is now protected from the heat, smoke, noise, and vibration. The operator also has to be protected from the hazardous chemical, Di-Hydrogen Monoxide (DHMO, CAS # 7732-18-5; see www.dhmo.org for further information on the hazards of this chemical) that is used in this process.

We have isolated the controls by moving them exterior to the machine and by putting a hood over the top to collect the heat and smoke. The operator is now protected from the heat, smoke, noise, and vibration. The operator also has to be protected from the hazardous chemical, Di-Hydrogen Monoxide (DHMO, CAS # 7732-18-5; see www.dhmo.org for further information on the hazards of this chemical) that is used in this process.

Step Three: Administrative or work practices do not protect the employees from hazards; however, they make them more aware of the hazards. Training is one of the most widely used administrative practices. The hazard is there, but now the employees are aware of the hazard and know that they need to lock out the machine before they try to clear the jam on the production belt.

Signs and posters are another awareness item that's used at this level.

In the work practice area, we can split the work between two or more employees. We have a punch press that generates over 90 dBA. Frank and Jim are both operators. Rather than have both of them work on the machine together, all day, we have Frank run the machine during the morning hours and Jim run it in the afternoon. We have not cut down the noise of the machine, but we've cut Frank's and Jim's noise exposures in half.

Step Four: At the bottom of the hierarchy; the last step, is PPE -- personal protective equipment. It is the last step, the bottom of the hierarchy, because the employees are responsible for their own safety. They need to be able to select the correct PPE, know how to use, and use it correctly.

We can ensure the employees know what the correct PPE is if they are involved in developing the Hazard Assessment that is required by OSHA under 29 CFR 1910.132(d).

A hazard assessment is a formalized procedure that looks at the hazards of the process and how to best protect the employees when they are involved in performing that process. Usually a checklist is used to ensure all of the hazards have been discussed. (An Internet search will turn up many forms that you can use, or check the www.ohsonline.com archives for a sample form attached to this article.) For example:

- Heat and cold

- Sound level

- Vibration

- Chemical exposures, vapors, and fumes

- Cut (laceration) hazards

- Compression hazards

- Radiation

- And others that may be specific to your company

Case Study

Let's do a case study: Process 607 is to neutralize acid. Jack, the operator, has to pump 100 gallons of waste hydrochloric acid (HCl) into a high-density polyethylene tank. Next, he turns on the air mixer on a low speed and slowly adds sodium bicarbonate (NaHCO3) powder, one scoop at a time. Every 15 minutes, he uses a dipper to take a sample and measure the pH with litmus paper until he has no change. He then opens the valve and discharges the neutral solution into the plant's waste stream.

First, we need to identify the hazards of this process. See whether you can find something that I missed.

1. Exposure to corrosive chemicals

2. Exposure to chemical dusts

3. Ergonomic problems with having to continuously scoop the powder or dipper samples

4. Ergonomic problems with continually having to turn valves

Next, we need to know how to protect our employees utilizing the hierarchy of controls.

1. Substitution or elimination: We cannot substitute or eliminate the HCl, but what about the NaHCO3? Rather than scoop it in, couldn't we purchase it as a solution and have it pumped in?

2. Engineering controls: We're already using some engineering controls in that we're pumping the acid into the tank, and we have an air mixer rather than having to mix it by hand. What about getting an in-line pH probe so the operator doesn’t have to continually take hand samples for pH adjustment? What about electrically operated valves to prevent the ergonomic problems?

3. Administrative/work practices: I'll let you come up with some suggestions.

4. PPE: How would you protect these employees? What PPE is needed?

What's Left to Do?

We ask, "How can we protect employees?" Many times, the first thing that people say is to give them a respirator. It is interesting to note that in the Respirator Standard, 29 CFR 1910.134(a)(1), OSHA says:

"In the control of those occupational diseases caused by breathing air contaminated with harmful dusts, fogs, fumes, mists, gases, smokes, sprays, or vapors, the primary objective shall be to prevent atmospheric contamination. This shall be accomplished as far as feasible by accepted engineering control measures (for example, enclosure or confinement of the operation, general and local ventilation, and substitution of less toxic materials). When effective engineering controls are not feasible, or while they are being instituted, appropriate respirators shall be used pursuant to this section." (italics for emphasis only)

This leads us back to the hierarchy of controls as being the best way to protect the employees. However, when they are "not feasible, or while they are being instituted, appropriate" PPE can be used.

If you have answers or questions, you can contact the author at regulatorymavin@yahoo.com.

This article originally appeared in the March 2013 issue of Occupational Health & Safety.