It's Personal

Back injuries are one of the leading workers' compensation claims. Repetitive motion injuries account for hundreds of thousands of lost workdays every year.

- By Chuck Paulausky

- Sep 01, 2014

Chester Carlson worked as a patent analyzer in the late 1920s, spending long, tedious hours making multiple copies of drawings and documents by hand. He was nearsighted and his cramped posture, combined with his arthritis, made the work unbearable. His solution came three years later, when he invented the copy machine!

Ergonomics is essentially the science of fitting the work to the worker. The term comes from the Greek words "Ergo" (Work) and "Nomos" (Laws) and basically means "the laws of work."

Ergonomics, as a science, draws on many disciplines, including biomechanics (the effects of internal/external forces on the human body), anthropometry (body measurements), and physiology (body functions), among others.

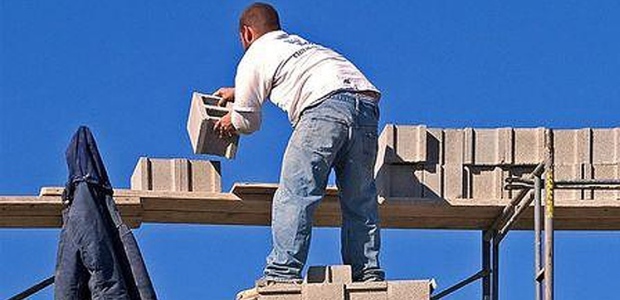

Some of the more familiar ergonomic concerns include musculoskeletal disorders (MSDs), repetitive motion injuries (RMIs), and carpal tunnel syndrome (CTS); the costs of these can be significant. U.S. employers shell out billions of dollars every year in medical costs, disability payments, and lost productivity because of workplace MSDs. Back injuries are one of the leading workers' compensation claims. Repetitive motion injuries account for hundreds of thousands of lost workdays every year.

Your wallet can cause sciatica! It's reported that a lawyer suffered aches and pains in his left leg, not far from where he kept a wallet that in the previous three years had been growing thick with charge cards. The patient's condition was described as "credit-carditis" but is more commonly called "back-pocket sciatica." The quick and simple remedy is referred to by doctors as a "wallectomy,' or wallet removal.

The ability to understand what ergonomics is, and how to identify some of the most common risk factors and practical solutions to use, will aid in reducing the number of ergonomic injuries.

Common MSD Symptoms

These are common symptoms of musculoskeletal disorders:

- Painful joints

- Pain, tingling, or numbness in hands or feet

- Shooting or stabbing pains in arms or legs

- Swelling or inflammation

- Pain in wrists, shoulders, forearms, knees

- Fingers or toes turning white

- Back and neck pain

- Stiffness or burning sensations

- Decreased range of motion and grip strength

- Inability to perform normal tasks

Risk Factors

Common risk factors include these:

1. Frequent manual material handling

2. Repetitive motions throughout the work shift

3. Awkward or stationary work positions

4. Unnecessary or improper lifting of heavy and awkward items. (Why six-packs? In the 1930s, the major breweries decided that six beers were "the maximum a woman could safely carry" while grocery shopping. Sorry, ladies.)

5. Using excessive force or localized pressure to perform tasks

6. Exposure to excessive vibration, extreme temperatures, and poor lighting

7. Exposures for long durations with insufficient rest periods

Solutions to these risks include:

- Keep the work in the comfort zone--the area above the knees and below the shoulders.

- Keep heavy or frequently-handled materials above the knees. Reaching down to lift heavy parts from the floor poses significant risk for back injuries.

- Keep work materials and processes in line with the spine. Avoid twisting whenever possible.

- Keep materials close. Reaching for materials, or lifting them at a distance from the body, increases exponentially the possibility of an injury.

- Keep the wrists in a neutral position. Bending, twisting, and skewing the wrists decreases strength and blood flow.

- Avoid holding awkward postures for extended periods. Poor postures or high forces for long periods of time are just as bad as repetition.

- Provide ergonomically designed tools and supports that eliminate awkward hand position, weight, and vibration.

- Eliminate contact stress. Pressure on soft body tissue will decrease blood flow and reducing oxygen and nutrients to the muscles.

- Design the workstation for a seated or standing position, as needed. Simply adding a chair to standing workstation isn't necessarily enough. The seated position needs to be correct, ergonomically, for the work being done. The same approach works for designing a standing workstation.

- Decrease exposure to vibration. High levels of vibration can increase onset of certain musculoskeletal disorders.

- Provide ergonomic assessments for general and individual workstations.

- Provide regular training for supervisors and managers for identifying ergonomic exposures and for the employees to implement changes and improvements, and also for safe lifting.

- Don't forget computer workstations, which are a common source of exposure for CTS and other ergonomic conditions.

I've got three final comments. First, ergonomics is not a one-size-fits-all approach. If you are going to provide fixes, ensure there is enough flexibility to make adjustments for differently sized workers. Second, much of ergonomics is very personal. An employee's personal factors over which an employer has no control, such as age, and some control, such as health, lifestyle, hobbies, etc., also will have an impact. Third, as an employer, you can put fixes in place and provide training in how to "do it right," but it can be difficult to get a worker to change lifelong habits, even if it's in the worker's best interests.

Do the best you can, and you should be able to reduce injuries and workers' compensation claims, as well as promote productivity and a healthy workplace.

This article originally appeared in the September 2014 issue of Occupational Health & Safety.