Combat Workplace Noise Pollution to Help Prevent Hearing Loss

Yikes! Hearing loss is the third-leading major U.S. public health issue.

- By Mary Padron

- Sep 01, 2015

According to John Hopkins Medicine and the Hearing Loss Association of America, "Hearing loss is the third leading major public health issue, affecting 48 million Americans, or 20% of the adult population." Arthritis leads the way, followed by heart disease. Sixty percent of people with hearing loss are either in the workforce or in educational settings.

One of the leading culprits of hearing loss is workplace noise pollution, which can lead to noise-induced hearing loss (NIHL). Over-exposure to high-noise environments occurs at factories, airports, construction sites, NASCAR races, rock concerts, and on our highways. According to the National Institute for Occupational Safety and Health, industries that include mining, agriculture, construction, manufacturing, utilities, transportation, and the military run the highest risk of NIHL noise pollution. Over-exposure to noise has serious consequences to our well-being and hearing, including auditory and non-auditory effects:

- temporary, mild, or permanent hearing loss

- tinnitus (ringing in the ears)

- physical and mental stress

- reduced concentration and communication

- loss of productivity

- increased probability of work-related accidents and injury

- heart palpitations

- aggressive behavior

- exhaustion

What is NIHL?

According to the World Health Organization, noise-induced hearing loss "is the most common, permanent, and preventable occupational injury in the world."

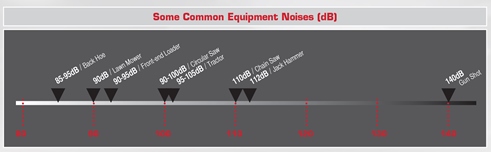

Noise-induced hearing loss may happen suddenly from an explosive type of blast or gradually over time as a worker is continuously exposed to noise above 85 dB without wearing proper hearing protection. Unfortunately, NIHL is an invisible pollutant, so it is often relegated to the back burner while eye protection and high-visibility protection take the job site spotlight. We can't see, taste, touch, or smell noise, and there is no obvious wound or blood—but every workplace should have a hearing conversation program, especially because hearing loss affects millions of workers.

What if you had to continuously listen to your blow dryer or to a juice blender (approximately 80 to 95 dB) for eight hours every day? Surely you would cringe at the thought and become quite agitated. Unfortunately, in numerous industrial settings, millions of American workers are assaulted and exposed to dangerous levels of noise (85 dB or above) every single workday.

How to Combat Workplace NIHL

Three weapons in your hearing loss prevention toolbox are (1) education, (2) "buy quiet" practices, and (3) the use of hearing protection devices (HPDs).

Education and training

Educate your workers and safety specialists about hearing loss by distributing informational brochures, by placing posters and caution signs in key traffic areas, and through annual training programs, which are required by OSHA "whenever employee noise exposures are at or above an eight hour time-weighted average (TWA) of 85 dBA or, equivalently, a dose of 50 percent, which is considered the action level."

"Buy Quiet” practices and other controls

When purchasing new equipment, nip noise in the bud by specifying the acceptable sound output for any new machinery. Be adamant about your sound requirements with your buyers and purchasing agents. The Centers for Disease Control and Prevention says that a national "Buy Quiet" purchasing movement is in place to get the military and corporations to buy "ear friendly" machinery. Hopefully, as technology improves, this "Buy Quiet" trend will gain greater momentum.

To deal with existing high-noise equipment and environments, consider engineering controls such as silencers, mufflers, and specially constructed acoustic walls to help remove sound. Administrative controls, such as moving workers to a safe area or limiting their time around the sound annoyance, is also effective in reducing noise exposure.

Hearing protection devices

When engineering and administrative controls are not successful in reducing noise exposure, hearing protection devices must be used. OSHA requires that employees be offered a variety of hearing protection devices, including ear muffs and ear plugs.

Just as ears, ear canals, and heads come in many different shapes and sizes, so do the many hearing protection devices available in the marketplace today. There are three primary types of noise related to HPD use: constant, intermittent, and impact/impulse. Constant noise requires single-use hearing protection, multi-use banded hearing protection, or ear muffs. Intermittent noise requires banded hearing protection or ear muffs. Impact or impulse noises are the most severe and require the highest passive noise reducers, double plugging, or electronic/active HPDs.

Which HPD Is Right For Your Safety Program?

Ear plugs

In the 1970s, NASA developed memory foam to assist astronauts with overwhelming G forces. This material was later adapted to make single-use ear plugs because of its slow recovery capabilities and softness. When choosing foam ear plugs, make sure the plugs are self-adjustable, non-irritating, comfortable, and offer the most protection, with NRRs of up to 33dB. Bullet, barrel, bell, and winged shapes exist to fit a large variety of ear canal shapes and sizes. Foam ear plugs are available in fluorescent safety focused colors to aid in compliance verification and many of them are made in the USA.

They come corded and uncorded, plus a variety of packaging options exist, including individually wrapped plugs or bulk options to be placed in dispensers for easy access in high-traffic, high-noise areas. Disposable foam plugs are ideal for big companies with lots of workers who go through large quantities of plugs quickly.

In addition to disposable foam ear plugs, reusable, custom molded, and baffle type ear plugs are available. Reusable plugs are made of silicone, polyvinyl, and other types of rubber. These non-porous plugs can be cleaned with warm water and soap. Custom molded plugs provide a super comfortable and personalized fit and are a favorite among workers, hunters, and musicians because of the proper fit. Baffle plugs have a sound-activated baffle/valve inside that will close when exposed to an impulse noise such as a gunshot. Baffle plugs feature technology that allows normal conversation when no impulse noise is present, allowing workers to hear commands and conversation.

Banded hearing protection and ear muffs

When hearing protection is intermittent, banded hearing protection can be a good lightweight alternative to ear muffs. Banded hearing protection is easy to remove and is designed to hang conveniently around the neck, which means the HPD is always within reach, doesn't touch dirty or oily surfaces, and allows for quick communication.

Ear muffs can be either passive or active. Both are easy to fit properly and come in a variety of shapes, sizes, and styles to fit a wide range of users. NRRs also vary greatly and can be as low as 17dB or as high as 30dB. Ear muffs can be worn over the head, behind the ear, under the chin, and as a hard hat attachment. They are available with lots of value-added features, such as gel-pad cushions on the cups, padded headbands, compact folding headbands, and multi-position headbands. Because ear muffs are very visible, they make it easy for safety officers to check for compliance.

Active ear muffs use electronic circuitry to cut or compress harmful impulse noises above 85 dB down to a safe level. Ear muffs that feature compression technology will reduce impulse noise to a safe level of 82dB while still allowing you to communicate. Ear muffs that use cutting technology will cut out all impulse noise completely. Some ear muffs also feature microphones that enhance/amplify hearing. Although the recommended use for active ear muffs is with the electronics on, they can be switched off. When the electronics are turned off, the active ear muff then functions as a passive ear muff and can be used in any environment. When the electronics are on, active ear muffs should be used only to protect against impulse noise.

When selecting hearing protection for your safety program always consider the type of noise—continuous or intermittent—the long-term cost, and worker preference. Worker compliance is one of the primary factors when considering the effectiveness of any HPD.

Why Hearing Protection Matters

All of our five senses—sight, taste, touch, smell, and hearing—are a blessing, and the sense of hearing is very important among the five. Think about all the precious moments you would miss if you couldn't hear. You couldn't hear "I love you" from your spouse or grandchild. You couldn't hear the music that makes you want to get up and dance. You couldn't hear the clink of crystal or the special words to loved ones when making a toast. When you can't hear properly, your performance at work declines and your impairment might even cause more accidents and injuries to occur. So protect hearing every day with quality hearing protection, not just because OSHA requirements and other federal regulations demand it. Do it because it is the right thing to do. Work hard. Stay safe.

This article originally appeared in the September 2015 issue of Occupational Health & Safety.