Temporary Electrical Power, Keeping it Safe!

If planned properly, many components that will be a part of the permanent and final installation could be a part of the overall temporary power for the project.

Why is it that some electricians think when it comes to temporary electrical installations, anything goes? Is temporary power on a construction site, renovation work, or even a carnival inherently safer than a normal installation? Even OSHA states that temporary power is a class less than what would be installed in a permanent installation. So why is it than that temporary electrical installations are commonly cited by OSHA during routine and focused inspections? Could it be because very little thought, planning, and execution are routinely involved in installing temporary power? Let's take a look at these installations and what are the governing requirements to be safe and efficient.

Temporary electrical power is utilized in many places, most commonly on constructions sites. It is also used in plants and buildings during renovation operations. Any electrical installation, whether it is permanent or temporary, should be installed according to all applicable codes, standards, and regulations. Another requirement that should always be followed is the one that states, ". . . installed in a neat and workmanlike manner." Many of today's construction sites are unsafe because the electrician or electrical contractor did not install an adequate temporary wiring, use equipment that is in a good working order, or take the precautions to protect the wiring and equipment being installed.

In many cases, the equipment used in temporary installations is not new and is not rated for the environment it is being used in. Proper planning should begin well before the electrician shows up to the job site on the first day. This includes determining what electrical loads that will be connected, such as temporary office trailers, construction material trailers, dewatering pumps, special tools, and equipment. While temporary electrical power is installed in some emergency situations, one should always consider what the environment it is installed in, what physical protection is needed, and how long it is going to be used. Using equipment that is rated for outdoor use is imperative if the equipment will be exposed to weather or other corrosive influences.

Using portable tools being supplied by extension cords is considered temporary work. OSHA and NFPA 70E state that when using portable cords or performing maintenance work, either a Ground-Fault Circuit Interrupter (GFCI) be used to supply the cord or an Assured Equipment Grounding Conductor Program, (AEGCP) be implemented to ensure safety of personnel. GFCIs have many installation and use requirements, including required monthly testing. If this is not documented on a construction site, OSHA may site the electrical contractor for not properly maintaining the temporary power system. If there is not a log of portable tools and cords being tested to assure proper continuity of the wiring through the AEGCP, OSHA may also cite this as a hazard.

Common Violations Associated with Temporary Power on Construction Sites

Some common violations found with temporary power on construction sites are wiring not rated or listed for the application, openings not covered in panels and enclosures, not using proper cable terminations, and not using the proper covers on receptacles and junction boxes at the job site.

Electricians sometimes use indoor rated cable for temporary since it is less expensive than cable rated for outdoor use. This is a clear violation of the listing of the cable if it is exposed to wet and damp locations during use. Care should be taken to ensure the wiring is supplied from a properly rated circuit and its capacity is not exceeded; not installing 15- or 20-amp wiring on a circuit capable of supplying 30- or 40 amperes. This type of installation is subject to overloading and the wiring could overheat and cause a fire.

Listed cable terminations should be used when installing any cable to a panel or disconnect. Using an EMT connector for multiple cables is not permitted, yet this unacceptable practice is seen on many job sites. Using the proper cable connector will keep the cable secure and prevent it from being inadvertently pulled out or damaged during construction activities. Panelboards and disconnects should always have holes and breaker openings effectively closed to prevent any foreign object from getting inside. Openings can also permit water and animal intrusion that could cause damage to equipment. Making sure equipment is maintained in a good working order according to the manufacturers' requirements is key so the equipment is to function as designed. In-use covers on receptacles permit an extension cord to be plugged in and not expose the receptacle to weather and rain, which could cause damage.

Temporary lighting is another aspect of temporary poser systems that is often overlooked and installed using incorrect components. All cords used for temporary lighting must be of the heavy-duty type and all lamps must be completely enclosed in a cage, lens cover, or other suitable containment for protection. Have you ever seen a worker carrying a metal pipe or tool and accidentally hit a light fixture, breaking the bulb? If the object the worker was carrying makes contact with the open lamp components, he or she could shocked or even electrocuted during such an incident. Temporary lighting circuits are not required to be protected by GFCIs, as mentioned earlier for receptacles and portable tool use.

OSHA 29 CFR 1926 is the regulation governing installations under construction. These electrical requirements are found in Subpart K and include similar requirements that can also be found in Article 590 of the National Electrical Code, (NFPA 70). Additional safety-related workplace requirements can also be found in NFPA 70E Standard for Electrical Safety in the Workplace. Other documents such as ANSI/NECA 200 Standard for Installing and Maintaining Temporary Electrical Power at Construction Sites, NECA's Guide to Temporary Power, and UL’s Guide Information for Electrical Equipment (White Book and UL Product Spec) also contain important information about equipment and installations for temporary power.

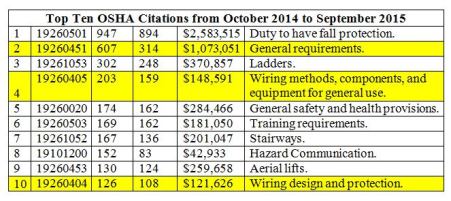

Three of the Top Ten Most Cited standards in building construction are related to electrical requirements: 1926.451 General Requirements, 1926.405 Wiring Methods, Components and Equipment for General Use, and 1926.404 Wiring Design and Protection, and they are numbers 2, 4, and 10, respectively, on that list. Since most if not all of these citations occur during the construction phase, they are demonstrative of issues found with temporary wiring on most job sites.

As can been seen in this summary table, there should be careful planning of all temporary power installations. If planned properly, many components that will be a part of the permanent and final installation could be a part of the overall temporary power for the project. This also makes later conversions to the permanent wiring system simple and easily achieved with minimal interruption on the project. The other key aspect of doing this is the physical protection and isolation of the wiring being installed. If the cable used is installed in conduit, for instance, it would be less likely to be damaged during an accidental contact.

As can been seen in this summary table, there should be careful planning of all temporary power installations. If planned properly, many components that will be a part of the permanent and final installation could be a part of the overall temporary power for the project. This also makes later conversions to the permanent wiring system simple and easily achieved with minimal interruption on the project. The other key aspect of doing this is the physical protection and isolation of the wiring being installed. If the cable used is installed in conduit, for instance, it would be less likely to be damaged during an accidental contact.

Another key issue on all construction sites with temporary wiring is that the electrical contractor/electrician needs to maintain exclusive control over the electrical installation. Only "Qualified Person(s)" as defined by OSHA and NFPA standards should be the ones installing, connecting, and servicing the temporary wiring installation. Qualified persons should understand implementing proper lockout/tagout procedures and how to troubleshoot an issue such as a "tripped" circuit breaker or bad Ground-Fault Circuit Interrupter. Too often, other trades with little or no training attempt to turn on breakers and reset other components without knowledge of the accidents they could cause. When electricians are beginning to test and commission the building wiring system during the final phase of construction, only qualified persons should be involved with the turning on and off of electrical circuits.

Don't treat temporary electrical power with any less importance that what is installed for permanent installation. Electricity does not know the difference between temporary and permanent; the hazards are the same. Take the time and effort to plan the installation, coordinate with utility and general contractor on project needs and available electrical services, and, finally, use only experienced and "qualified" personnel to install and maintain the temporary system to ensure its safety and performance.

Keeping workers safe on all projects is a shared responsibility between employees and employers. Maintaining the safety and integrity of the temporary electrical wiring system is an important part of that.

How OSHA and NFPA Standards Define "Qualified"

1926.32(m)

"Qualified" means one who, by possession of a recognized degree, certificate, or professional standing, or who by extensive knowledge, training, and experience, has successfully demonstrated his ability to solve or resolve problems relating to the subject matter, the work, or the project.

NFPA 70, National Electrical Code, Definition of "Qualified Person"

"Qualified Person": One who has skills and knowledge related to the construction and operation of electrical equipment and installations and has received safety training to identify and avoid the hazards involved.

NFPA 70E Standard for Electrical Safety in the Workplace, Definition of "Qualified Person"

"Qualified Person": One who has demonstrated skills and knowledge related to the construction and operation of electrical equipment and installations and has received safety training to identify and avoid the hazards involved.

This article originally appeared in the September 2016 issue of Occupational Health & Safety.