Selecting the Best Hand Protection for the Task

When the correct level of persistence is applied toward identifying the hazard exposures, true cost savings will be seen every time.

People who play sports that require a swing of perfect alignment, such as golf, enjoy the outcome when the "sweet spot" is felt. The question is, how did they find the sweet spot? Did they get lucky with one swing and struggle locating it the next time, or do they regularly hit the "sweet spot" due to their dedication toward persistence?

Today, more than ever, we are seeing customers select their hand safety protection based off one of two things. There is either a lower price point than what they currently have or they felt a sense of connection with a sales representative who promised some type of magic in their glove. We feel the lack of persistence and dedication toward identifying the hand hazards and exposure levels before selecting the proper hand safety protection keeps these customers from ever seeing the cost savings in locating the "sweet spot."

We use a seven-step process1 that helps to identify the correct method toward locating the "sweet spot." This method helps to guide the user to make the best decisions on all levels of hand protection needs within a facility.

This past summer, we had the opportunity to assess a manufacturing facility that was having difficulty meeting its annual PPE budget. Below are the steps we followed to locate their "sweet spot."

Making the Hazard Assessment

Ever wonder why a forklift operator is wearing the same cut level of hand protection as the sheet metal operator? And even worse, their monthly usage is the same? Let's take a look at this even closer to uncover how the "sweet spot" was found.

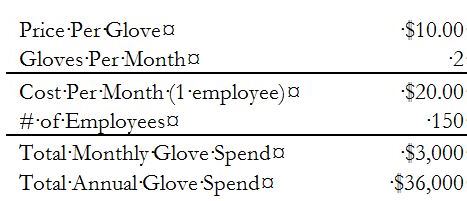

Let's begin by looking at the sheet metal operator's glove use. Through the proper hand hazard assessment, we identified that the sheet metal operator needs a level of cut 4 protection. The glove selected costs $10 each. Through understanding the exposure level, it was determined that two pairs of the selected glove would be used each month by this one operator.

Now, let's look back at the forklift operator's hand protection. Remember, he is using the same glove and has the same monthly usage.

Through the proper hand hazard assessment, we have identified that the forklift operator has no exposure to cut hazards. Truly, what is needed is superior grip with true feel.

Through conversing with this operator, it was discovered that the he liked the sheet metal operator's safety gloves because of their gripping capabilities. After reviewing a few options, the correct glove was selected. The new selected glove costs $5.00. With the proper training and communication of expectations, it had also been determined that the operator only needs one pair per month.

The correct level of protection:

When the correct level of persistence is applied toward identifying the hazard exposures, true cost savings will be seen every time. Staying out of the "sweet spot" is when the magic glove is introduced and only the savings of $1.50 per pair is viewed as a win. By the sales representative never walking onto the plant floor to evaluate the hazards, you could still be overprotecting the operator, causing a higher-priced level of hand protection to be used.

These behaviors are seen every day in multiple industries, which cause companies to struggle meeting their PPE budgets. Many times, procurement members are being measured on an overall immediate cost reduction while safety members are being measured by an overall annual reduction in injuries. When both sides come together and understand that greater savings can be had by taking a deeper look up front into all department hazards, both parties will be successful.

By incorporating the seven-step approach, you will benefit greatly, which will keep you in:

The Sweet Spot!

References

1. https://ringersgloves.box.com/v/7-step-process

This article originally appeared in the November 2016 issue of Occupational Health & Safety.