Pushing Past Leading Indicators: Measuring Value and Balanced Scorecards

Are the things you are doing adding value? Are levels of compliance increasing? Are beliefs and behaviors changing?

Results, inputs, value, or correlation? What receives the main attention within your approach to safety measurement? Safety measurements are evolving, and it's about time. About 150 years ago, safety, if considered at all, was measured by the amount of work performed or dollars spent. History tells us that in the creation of the first skyscrapers in the late 1800s, with the number of floors built, there was a certain number of fatalities expected. While we have come a long way, safe work is still measured largely by the numbers of incidents or injuries compared to number of hours worked. As the old adage goes, "Be careful what you measure, as people will work towards those measurements." Moreover, what leaders or regulators pay attention toward, others will work to satisfy.

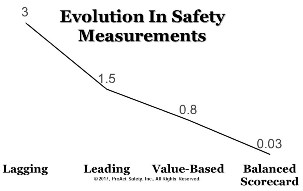

In ProAct Safety's consulting practice, an evolution in safety measurements occurring at key points in safety performance improvement has been identified, as shown in the accompanying image. While the numbers indicate the average Total Recordable Incident Rate (TRIR) where client companies have moved toward improvement, let this serve only as a visual to reinforce the thinking needed for change. The level of maturity of safety excellence thinking among senior leadership is the most crucial impetus for searching for a better way to measure things.

Lagging Indicators—How did you do? These results-based trailing indicators (injury rates) should be the most familiar concept in safety measurements and are what most safety professionals and business leaders are held accountable for. Arguably, this is largely because of the mindset created due to how business leaders are traditionally measured themselves. How much did you sell today? How much did you produce? How far did you drill? How many new customers? How many injuries occurred? Eventually leaders come to the realization that more of the same doesn't produce change and the absence of injuries doesn't indicate the presence of safety. Safety is more defined by what you do to affect the results. Just as was learned in medicine, the absence of visible disease doesn’t indicate the presence of health. Instead, doctors change their focus on how to create health.

Leading Indicators—What are you doing to affect your results? In most companies, this means asking, "Are we working our process?" In safety, leading indicators often focus on number of safety meetings, audits, observations, safety shares, Job Safety Analyses completed, stop work authority exercised, suggestions or safety work orders submitted, or hours or days trained. These are indeed valuable to the organization and valuable to measure and indicate a maturing of safety practices, culture, and implementation of management systems. However, they can lead smart people to fall into the correlation-causation trap, leading individuals to believe that because they conducted this training, put this program in place, or increased attention toward safety, this is why the results improved. Sometimes this is true. Sometimes it is because of normal variation in performance or due to the Hawthorne effect, where performance improves because of the measurement and focus. Sometimes, we are just luckier one year over others. In medicine, measuring the number of days exercised or calories consumed and burned does not guarantee a healthy patient. How do you know what you are doing is the real reason for performance change? Is what you are doing adding value?

Value-Based Indicators—Are the things you are doing adding value? Are levels of compliance increasing? Are beliefs and behaviors changing? Some simple questions should be asked of any new approach or intervention: 1) Why are you doing this? 2) How does this meet your data-driven strategic objectives? 3) How will it contribute to an improvement in lagging indicators or improve the culture? 4) How will you know for sure? In health care, blood pressure is an example of value-based measurement. If you exercise and make the right meal choices, how does this affect your blood pressure? If your blood pressure is normal, you will have greater confidence you have a healthy heart. As we know, however, this isn't the only consideration for overall heart and body health. How does one process affect another? How does what we do in one area affect another?

Balanced Scorecards—How does what you do affect the many inputs, processes, performance, and results? Popularized in 1990 by Robert S. Kaplan and David P. Norton in their groundbreaking research and many writings on the subject, a balanced approach to measurements is the preferred system for high-performing and highly reliable organizations. A focus on the strategic agenda and desire to understand the "why" behind performance and results have driven many organizations to place a few key indicators on a scorecard that allows for insight into the relationship between inputs and outputs of different areas and processes. While in health care there are a few critical indicators, physicians regularly measure the efficacy of the intervention and how other interventions affect the body and mind.

The bottom line is to measure what you want, not just what you don't want. Measure so you have confidence into the reasons for the results. Measure to understand how the many process inputs not only affect the results, but also each other. Safety measurements aren’t one- or two-dimensional. Many of the clients we work with realize transformative improvement not just by doing more, but by doing things better. Without measuring the interconnectedness of activities and results and how they affect each other, how confident can you be in the "why" between your inputs and outputs?

This article originally appeared in the September 2017 issue of Occupational Health & Safety.