The Hazards You Face: Navigating COVID-19 Face Mask Guidance & FR Hazards in the Workplace

How do face coverings help in the workplace? How should an employer approach mask selection when additional workplace hazards are identified?

- By Catherine Brear, Allie Fletcher

- Aug 01, 2020

In the face of the COVID-19 outbreak, we are living through truly unprecedented times. Not only is COVID-19 caused by a new coronavirus, SARS-CoV-2, but studies and guidance are constantly evolving as the number of cases fluctuates in many areas of the world.

One of the areas where guidance continues to evolve includes face coverings and masks. How might wearing face coverings or masks help slow the spread of COVID-19? What does this look like in the workplace? How should an employer approach mask selection when additional workplace hazards are identified?

As of April 2020, the U.S. Centers for Disease Control and Prevention (CDC) recommends “wearing cloth face coverings in public settings where other social distancing measures are difficult to maintain… especially in areas of significant community-based transmission.”1 Per the CDC, “cloth face coverings provide an extra layer to help prevent the respiratory droplets from traveling in the air and onto other people.”2 If everyone wears a cloth face covering when out in public, the risk of exposure to the coronavirus can be greatly reduced for the community. It’s important to note that these masks should be used in addition to social distancing, frequent and thorough hand-washing, and other prevention measures.

With this guidance, the CDC recommends your cloth face covering:

- fits snugly but comfortably against the side of the face

- completely covers the nose and mouth

- is secured with ties or ear loops

- includes multiple layers of fabric

- allows for breathing without restriction

- can be laundered and machine dried without damage or change to shape

- should be washed after each use

Applying CDC and OSHA Guidance to the Workplace

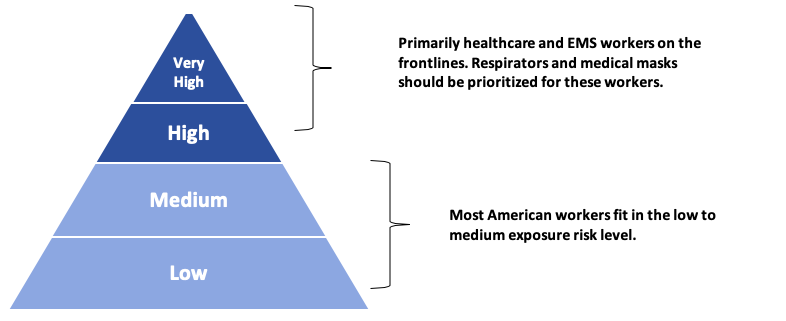

According to the Occupational Safety and Health Administration (OSHA), worker risk of occupational exposure to the virus depends on a worker’s ability to social distance—at least six feet of separation—between people known to be, or suspected of being, infected.3 To help employers determine appropriate precautions, OSHA has divided job tasks into a pyramid of four risk exposure levels: very high, high, medium, and low risk.4 The four exposure risk levels represent the probable distribution of risk and are represented in Figure 1.

Figure 1- Classifying the Risk of Worker Exposure: OSHA Occupational Risk Pyramid for COVID-19

The very high and high categories are primarily associated with healthcare and emergency medical services (EMS) workers on the frontlines in direct or close contact with confirmed or suspected COVID-19 patients. Most American workers—including those in manufacturing and industrial facilities—will likely fall in the low or medium exposure risk levels. Those who do not have frequent close contact with others would fall into the low risk category, especially if additional controls have been put into place to limit how many workers are in a given work area at one time. Medium exposure risk jobs include those that require frequent and/or close contact with people (i.e., within six feet of one another).

Face Covering Options to Consider

There are a variety of different types of face coverings available today—respirators, medical masks, and a new, third category of masks that has developed from the CDC guidance, which we are calling social distancing face coverings. These categories of masks have different properties, are tested to different standards, and are used for different purposes and settings.

Respirators (like N95 masks) are designed to reduce exposure to both large and small particles and are individually fitted to the wearer to ensure a proper seal around the nose and mouth. When properly fitted and donned, there is minimal leakage when the wearer inhales.5 An N95 respirator is considered essential personal protective equipment (PPE) for our healthcare workers on the frontlines who fall into those very high and high risk of exposure categories.

Medical masks—the next category—includes surgical masks, procedure masks and patient care masks. These masks are designed to protect the wearer from bodily fluids and other large droplets while also preventing the spread of respiratory droplets from the wearer to others.6

These masks are looser fitting, so leakage occurs around the edge of the mask. Thus, medical masks do not provide the wearer reliable protection from inhaling those smaller airborne particles and are not considered respiratory protection.7

Finally, we have social distancing face coverings. This category includes any cloth, reusable, non-medical face covering meant to be worn by the general public or others in OSHA’s low to medium risk exposure categories to provide a barrier between the wearer and other people in case the wearer is infected. As of the writing of this article, there are no industry standards in North America specifying performance requirements for these masks. However, other countries have begun to develop standards for these face coverings, and it is likely only a matter of time before North America follows suit.

The French Association Française de Normalisation (AFNOR) standard S76-001 (developed in March 2020) and the Turkish Standards Institute (TSE) K599 standard (developed in May 2020) were both crafted in response to the COVID-19 spread and the need for this “social distancing” category of masks.8,9 Similar to the U.S. CDC guidance, both standards specifically warn that these masks are not considered medical devices or PPE, and do not exonerate the wearer from primary prevention measures such as social distancing and frequent hand washing. These standards define various requirements with regard to breathability, filtration and design. They also include guidelines on proper use, washing and drying and recommended materials.

What to Look for in a Face Covering

Building on the CDC guidance, we have compiled some considerations when selecting face coverings. Ultimately, it is the employer's responsibility to evaluate the risk of exposure to the virus as well as the hazards present in the work environment in order to protect employees effectively.

- Breathability. Can you breathe through the material with little restriction?

- Filtration efficiency. There are different levels of performance when it comes to filtering out particulates, viruses or bacteria. Does your application require an N95 respirator, or are you trying to comply with the CDC’s recommendation for cloth masks?

- Design/Comfort. Both play a big role in whether or not your employees will wear the coverings properly. Consider if ties or elastic work best, the shape and fit of the covering on the face, adjustability or sizing. When it comes to comfort, how soft and lightweight is the material? How quickly does it wick away or absorb moisture from breathing or sweating?

- Potential inhalation hazards. Are there any potential hazards from the mask material?

- Length of intended use. Is the intent for the worker to wear the face covering for a full shift or only when performing a certain task and/or in close contact with others?

- Ability to decontaminate. Is the face covering reusable? If so, how can it be decontaminated appropriately and how often? How durable is it to multiple launderings?

- Work environment. What specific hazards are present? Is it possible to protect against all hazards present, or do you need to prioritize which hazards have higher risk?

Selecting Face Coverings for a Flash Fire Hazard Area

One popular question is how to properly select face coverings for work areas that require flame-resistant (FR) garments.

Although many people can use cotton masks or disposable medical masks when social distancing cannot be achieved, some essential industrial workers require face coverings that can withstand flash fire hazards. Most medical masks are made of materials like polypropylene, which could melt, drip and continue to burn in a flash fire or other thermal exposure, increasing the potential burn injury to the wearer. OSHA 1910.269(l)(8)(iii) specifically prohibits clothing that could melt, ignite and continue to burn when exposed to flames.10

To meet the CDC and OSHA guidance in areas where a flash fire hazard has been identified, employees must wear FR face coverings. FR face coverings will not melt, drip or burn when exposed to heat or flames. If you have identified a flash fire hazard and your employees are wearing FR garments, then they should also be wearing FR face coverings.

In addition to the general mask selection criteria noted previously, consider the following when selecting an FR face covering:

- Inherency. Inherently heat- and flame-resistant materials have FR protection that is built into the fibers and can’t be washed out or worn away. Is the protection inherent to the fabric?

- Durability. Assuming the mask is reusable, how many wash cycles will it withstand? Will washing or decontamination compromise any FR properties of the mask?

Match your FR PPE

As new guidance continues to evolve, it is more important than ever—and can be even more challenging—to quickly adapt to the changing needs of workers during the COVID-19 pandemic. Remember to evaluate the risk of exposure to the virus as well as hazards present in your work environment in order to protect workers effectively. And if you need assistance with navigating the challenges you face, consult with an expert.

REFERENCES

1 https://www.cdc.gov/coronavirus/2019-ncov/prevent-getting-sick/cloth-face-cover.html

2 https://www.cdc.gov/coronavirus/2019-ncov/prevent-getting-sick/how-to-make-cloth-face-covering.html

3 https://www.osha.gov/Publications/OSHA3990.pdf#page=20

4 https://www.osha.gov/Publications/OSHA3990.pdf#page=20

5 https://www.cdc.gov/niosh/npptl/pdfs/UnderstandDifferenceInfographic-508.pdf

6 https://www.osha.gov/Publications/OSHA3990.pdf#page=20

7 https://www.osha.gov/Publications/OSHA3990.pdf#page=20

8 https://masques-barrieres.afnor.org/

9 https://www.tse.org.tr/Icerik/DuyuruDetay?DuyuruID=5919

10 https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.269

This article originally appeared in the August 2020 issue of Occupational Health & Safety.