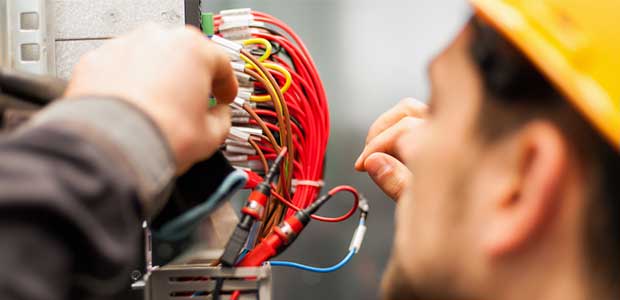

Safety First—Mitigating Safety Risks in Electrical and Control Systems

Components like proper PPE, Lockout/Tagout and clear hazard communication are essential to implementing “safety first” practices.

- By Zach Ganster

- Dec 01, 2020

Go into any organization today and it will not take you long to find the words “safety first” posted on a sign, placard or banner. However, “safety first” should not just be a corporate slogan. It is undoubtedly important to many occupational safety managers in manufacturing. But are safety managers covering all their bases in their safety program to ensure that safety is truly coming first? And should maintaining a “safety first” mindset fall solely on the shoulders of the occupational safety manager?

When approaching “safety first” concepts, safety managers should, at a minimum, address safety compliance requirements by providing all the tools and components of a comprehensive safety program.

Components like proper PPE, Lockout/Tagout (LOTO) and clear hazard communication are essential. But what if we took the slogan “safety first” literally and looked to employ methodologies like “Prevention Through Design” and tools like the hierarchy of controls to our safety programs? A Prevention through Design approach focuses on incorporating technology that touches on the more advanced levels of the hierarchy of controls pyramid, ultimately “designing out the hazard.”

The higher up you move in the hierarchy, the less risk of human error. Many times, these hazards can be reduced by implementing innovative safety products and strong network infrastructures during the design phase, so the hazards never reach the plant floor.

Excellent examples of this would be Absence of Voltage Testers (AVT’s), Data Access Ports, network security, data communications and assessment tools. The “safety first” mentality should not only apply to our everyday job responsibilities, but to how we are designing our equipment and network infrastructures.

By doing this, companies can provide multiple layers of safety assurance to help constantly protect their manufacturing employees and equipment.

Combining “Safety First” Culture and the Next Generation of Electrical LOTO

LOTO prevents the accidental start-up or release of stored energy during set-up, maintenance and servicing of equipment by preventing access to the energy source. Effective implementation prevents an estimated 120 fatalities and 50,000 injuries each year. In contrast, ten percent of all serious workplace injuries can be attributed to the absence or ineffectiveness of lockout/tagout procedures.

Proper LOTO policies improve the effectiveness and outcomes of workplace safety programs. However, as we enter a new year, companies must evaluate, improve and expand their electrical safety processes as standards, regulations and technologies evolve. When thinking about electrical hazards, it is essential to take a comprehensive view. Not only does electricity impact all facilities, but it also affects everyone present at the worksite.

Electrical safety programs must address not just electrical work, but electrical hazards encountered during normal plant operations as well as routine maintenance, unscheduled service, cleaning and repair situations.

An electrical safety program will impact electricians, non-electrical maintenance workers, technicians, operators, cleaning crews and groundskeepers.

As manufacturing processes become more connected, it is not uncommon to see the need for multiple trades to access electrical equipment increase and more distractions introduced. Even the best workers have bad days, and experienced workers can become complacent.

Consequently, most incident investigations reveal multiple errors or deviations from the process. To establish a best-in-class electrical safety program, it is essential to look beyond compliance and . embrace new technology and best practices that address human factors. This is the idea behind the Absence of Voltage Tester (AVT).

The AVT is a permanently mounted tester used to make the absence of voltage verification step safer and less complex.

Pushing a button initiates the absence of voltage test from outside the equipment before doors and cover are removed, greatly reducing electrical hazards exposure. Also, the AVTs are automated, performing steps that typically take anywhere from 10-20 minutes in less than 10 seconds, reliably reducing the many human error opportunities that exist when using a portable tester.

AVTs are only the first step in innovation to the electrical LOTO and verification process. Although the AVT can be used as a standalone tester for the verification step, some products are equipped with a set of output contacts that allow the AVT to be integrated with other components or automation systems.

One example is the combination of the AVT with an electronic lock. When utilized at the control panel or equipment level, this combination can not only verify the absence of voltage without exposure to electrical hazards, but it can also physically prevent an enclosure from being opened or a manufacturing/robotic cell from being entered until the absence of voltage is confirmed.

Bringing access control to the equipment level provides enhanced safety and security levels on the plant floor. This approach also reduces downtime since an electrician is not needed to perform the verification step for LOTO applications not requiring electrical work.

New technology often requires changes in behavior and habits, and electrical safety technology is no different. Understanding technology and where best to apply it is crucial to establishing trust and confidence, making adoption easier.

There are several features to look for when evaluating technology like AVTs and access control to ensure they will be reliable and increase the safety of operations. Look for products that include:

- Active status indicators. Positive feedback that the product or system is working is critical, and active indicators are one way to achieve that.

- Fail-safe designs. The safety functions in electrical products need to be designed so that they will default to a safe state if they fail.

- Functional safety. Used to prevent and control dangerous failures and can be used to measure the reliability of a safety function with a SIL (safety integrity level) designation.

- Standards. Look for UL listings and to standards like NPFA 70 and 70E for best practices with electrical installations and procedures.

It’s important to continually identify and assess potential hazards. As advances in technology occur and new products are released, new ways to mitigate old hazards will become viable. Designed-in control measures are more effective and provide greater business value than other administrative approaches such as training or PPE alone.

AVTs and access control are just the beginning of modernizing electrical LOTO. Manufacturing spaces are full of unknown hazards. In addition to focusing on safety during the design phase, assessments or audits should be periodically planned into the process to re-visit the integrity of safety programs and systems.Safety manager, IT personnel, engineers and operators all see safety through a different lens, so it is important to include everyone during assessments and audits. Remember, safety should be the focus of both employees and managers.

As companies prepare for the future of electrical safety, the use of Prevention through Design to mitigate risk at equipment or frequently performed tasks will take electrical safety to the next level and prepare them for the advancements ahead.

This article originally appeared in the November/December 2020 issue of Occupational Health & Safety.