By Michele Ostrove

How the flexible polyurethane foam manufacturing industry manages the handling of toluene diisocyanate.

By Jerry Laws

This year's conference will be year four for the popular Ignite sessions, which are five-minute talks on pretty much any topic.

By Ralph Metzner

The plan should be considered a living document, reviewed and updated on a regular basis as the emergency team sees fit.

By Luke Allen

CNP systems have demonstrated the ability to accurately and consistently measure known levels of respirator leakage.

By Fred Elliott

Eyewash stations and showers must be easy for an injured person to operate and must work reliably whenever they are needed—so the equipment must be tested weekly.

By Karen D. Hamel

Reviews uncover revisions that will need to be made, procedures that will need to be updated, and training that may need to be changed.

By Rob Brauch

The convergence of wireless devices, low-cost sensors, Big Data, and crowdsourcing will change the way you assess risk in your workplace.

By Amanda Yerke

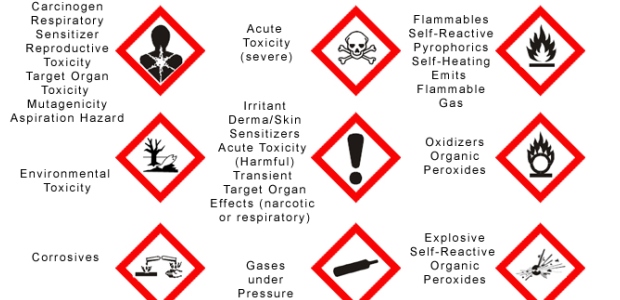

According to OSHA, any chemical that could possibly cause any physical or health effect under expected conditions of use or reasonably anticipated conditions of misuse is hazardous.

By Reginald Gates

It is most effective to have one person in charge of creating the emergency preparedness plan.

By David Kennedy

Implementing a housekeeping routine to mitigate combustible dust minimizes explosion risk.

By Robert Pater

The most Safety- and creatively-effective companies are “Leader-full,” with leadership functions distributed and filled by many people throughout the organization.

By Shawn M. Galloway

We need to provide a safe environment for our workers, and we need to coach (providing a balance of consequences for if they act this way and if they don’t) for specific safety performance, as well.

By Jerry Laws

Updating the PELs is an important issue. OSHA’s RFI is broader than that, encompassing other strategies it could use to address workers’ exposures to hazardous chemicals.