By Sam Boraas

In tough, high-hazard environments, fire extinguishers are put to the test.

By Prabhu Soundarrajan

Acquiring the latest software for safety management and monitoring can make a significant difference. The key is connected technology.

By Fred Elliott

Both 1910.1200 and 1910.120 are critical to those working with hazardous chemicals and to their supervisors.

By Peggy Kroesch

Eyewear that is uncomfortable or structurally compromised simply doesn't get worn.

By Scott Francis

The updated NFPA 70E can be explored through the lens of parties impacted. Through analyzing party responsibility, safety engineers and managers can make informed decisions to comply.

By Tony Quebbemann

Adequate training, protection from exposure, and disciplined use of ground fault circuit interrupters are integral to keeping workers safe.

By Chris Koester

Warning! This is a test. This is a test of the Emergency Response Plan.

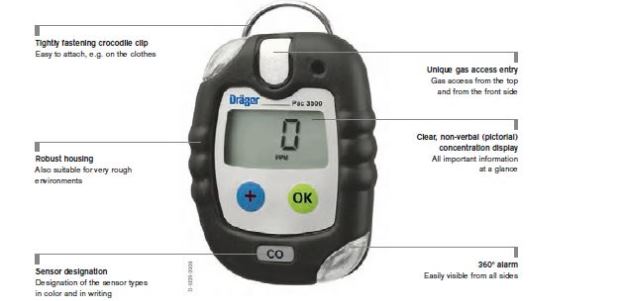

Safety should always be of the highest priority—it is the reason these detectors were invented, after all.

By Michael Hallock

After identifying the hazards, the exposure levels from the exposure assessment must be compared to the permissible exposure limit, as set by OSHA, to determine whether respiratory protection is needed.

By Jerry Laws

We congratulate the 23 winners in our ninth annual contest recognizing the most innovative new safety products.

By Todd Grover

We have found that only about 10 percent of companies run effective lockout programs. In fact, we have observed that up to three-out-of-ten employers have no lockout program at all.

Wind turbines are getting larger and larger. Some turbines' nacelles can be about 160 meters—about 525 feet—above the ground, and the blades can be about 75 meters long.

By Robert Pater

What you think helps actually can make things worse. For example, increasing coefficient of friction can increase trips when footing "sticks" on a surface.