December 2018

- PROTECTIVE APPAREL: Six Important Changes Reflected in NFPA 2112-2018 Updates

- PROTECTIVE APPAREL: The Essence of Cold Weather Protection

- IH/GAS DETECTION: Gas Detection for Safe Confined Space Entry

- FACILITY SAFETY: Ready for the Cold?

- HAZMAT: EU-OSHA Seeks Better Management of Dangerous Substances

- ELECTRICAL SAFETY: Workplace Safety Saves Lives and Money. Is Your Facility Prepared?

- FIRE AND EMERGENCY: Training Employees to Recognize and Respond to Hazards

- FIRE AND EMERGENCY: Safety Beyond the Basics: What Can We Do to Be Prepared?

- WELDING SAFETY: Key Protections for Arc Welders

- LOCKOUT/TAGOUT: Staying Safe During Equipment Maintenance

- VISION PROTECTION: Getting Eye and Face Protection Right

- NEW PRODUCT OF THE YEAR: 2018 NPOY Contest Winners Honored

- BEHAVIOR-BASED SAFETY: BBS & HOP = Predictive-Based Safety

- STANDARDS: Dollars and Sense: The Business Case for Safety Management Systems

- DROPPED OBJECTS: The Number 1 Reason to Demand Your Tool Tether Be Dynamic Drop Proven

Cover Story

By Scott Francis

From cold weather insulation guidance to labeling, these are the changes you need to know to be well informed when specifying an FR PPE program designed for flash fire hazards.

Features

By Jessica Davis, Jerry Laws

OH&S congratulated winners of the tenth annual contest during the 2018 National Safety Council Congress & Expo in Houston.

By Jerry Laws

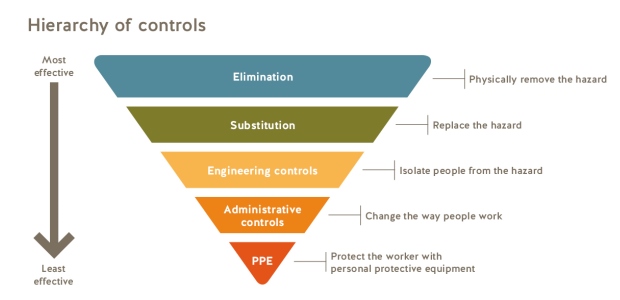

Controlling the risks is done by applying the hierarchy of controls: elimination, substitution, engineering controls (such as ventilation systems to remove welding fume), administrative controls, and finally, PPE.

By Karen D. Hamel

Employees should be trained to respond appropriately to each scenario that is applicable to their workplace, which could mean training everyone not only to evacuate, but also to shelter in place and how to lock down areas.

By Chuck Pettinger

With accuracy rates as high as 86 percent, predictive analytics have helped organizations save lives.

By Melissa Gerhardt

Lightweight garments may seem counterintuitive for protecting against the cold, but layering up lightweight garments is one of the best ways to combat the cold and remain comfortable.

By Nicholas Voss

A device may pass a static test with flying colors, but when put into a real-life situation it may still fail and break, and that's bad for anyone standing underneath.

By Fred Elliott

The ESENER-2 survey found 38 percent of EU companies reporting that chemical or biological substances in the form of liquids, fumes, or dust are present in their workplaces.

By Todd Grover

ISO 45001 and the revised ANSI/ASSP Z10 SMS Standard will help safety professionals make the case to executive leadership that integrating safety and health into existing business management systems is both financially prudent and increasingly feasible to achieve.

By Paul Smith

Both your employees and your facilities should be well prepared for cold weather hazards.

By Jay Smith

Workplace safety and operational performance are critical factors to protect all of your assets: your employees, facilities, and financial interests.

By Jerry Laws

It's more than a best practice—it is essential to test the air prior to and during entry, as OSHA requires.

By Brian Welch

If we can allow employees adequate time to plan, review technical information, practice, and check available resources, together we can reduce the workplace fatalities each year.

By Jerry Laws

Having an eye and face protection program in place will boost the chances employees will use their PPE correctly.

By Jerry Laws

Lockout/tagout ranked fifth on OSHA's list of the Top Ten most-violated standards during fiscal year 2017 and again in FY2018. There were 2,877 violations of 1910.147 during FY2017 and 2,944 during FY2018.

Departments

By Jerry Laws

Alliance partners will provide education and support to brewery owners and their employees on safety and health issues specific to craft brewers, as well as risks unique to their industry.

By Robert Pater

Even with aging workforces, injuries can be greatly reduced with a blend of best engineering controls and practical training.