"This was a horrific and preventable situation," said Labor Secretary Hilda Solis. "The employer was aware of the hazards and knowingly and willfully sent workers into a confined space with an explosive and toxic atmosphere."

The Connecticut-based metal finishing company also was cited for not establishing a regulated work area and ensuring contaminated protective clothing remained in the work area, and for not conducting cadmium exposure sampling.

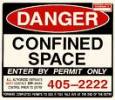

The 33 serious violations include a lack of training, electrical hazards, inadequate personal protective equipment, failing to implement an adequate hazard communication and respiratory protection program, and failing to properly handle confined spaces.

Inspections at the facility found improper bloodborne pathogens control, amputation hazards, noncompliant confined space entry, improper storage of fuel and oxygen, and more.

"While it's fortunate that no collapse occurred, excavation safety cannot rely on good fortune," said OSHA Area Director Brenda Gordon. "Required safeguards must be in place and in use at all times."

In its fifteenth OSHA inspection since 1974, the company was charged with nine willful, four repeat, and 17 serious violations, including hazards of confined space entry and combustible dust.

This contractor has been inspected by OSHA 25 times since 1991 and has been issued numerous willful, serious, and repeat violations, including many lead violations, the agency said.

If you are responsible for the health of your gas detection program, now is a great time to get it into shape. And if you want to keep your gas detection program healthy and keep your people going home safely at the end of each day, exercise your data analysis muscles by following a routine of reviewing the information stored in your gas detectors.

It's time we laid down the law on what, where, and how often to calibrate portable gas detectors.

"Each one of these inspections resulting from anonymous complaints reflects a serious disregard for the safety and health of the miners who work at these operations," said Joseph A. Main, assistant secretary of labor for mine safety and health. “What's especially troubling is that one of the complaints came in just days after the explosion at Upper Big Branch Mine."

The latest semiannual regulatory agenda does not advance the rulemaking except to give an October 2010 date to complete analyzing comments submitted in 2008. EPA's agenda says NPRMs will be issued in July 2011 to enhance pesticide protection for applicators and agricultural workers.

Cited violations against the company include failing to provide safe work practice procedures for hot work in a confined space, failing to prevent cutting operations in the presence of explosive atmospheres, and the lack of procedures for summoning resuce and emergency services.

CSA Z1006, Management of Work in Confined Spaces, would be the country's first comprehensive national standard on the topic and would solve a puzzling problem: jurisdictions haven't agreed on a consistent definition of "confined space."

"West Virginia is in mourning today,” said Representative Nick J. Rahall II on location at the mine, which is in his district. “We will scrutinize the health and safety violations at this mine to see whether the law was circumvented and miners’ precious lives were willfully put at risk, and there will be accountability.”

Under RECA, people in the following claimant categories may receive payments: uranium miners, millers, and ore transporters; people who were present at nuclear weapons tests; and people who lived in certain areas "downwind" of the Nevada Nuclear Test Site.

"Unprotected trenches can become deathtraps in an instant when cave-ins occur," said Richard S. Terrill, OSHA's regional administrator in Seattle.

Specifically, the agency found instances of improper transfer and storage of flammable liquids; lack of specific lockout/tagout procedures and training to prevent the unintended startup of machines during maintenance; lack of hearing protection; inadequate respirator training, fit-testing, medical evaluation, inspection, and maintenance; unguarded grinders; and more.

"Out of sight does not mean out of mind when it comes to underground petroleum storage tanks, and it is critical that facilities monitor their tanks and make sure they are not leaking," said EPA Regional Administrator Judith Enck.

"This case is a clear and grave example of the human cost incurred when required fall protection safeguards are absent, ignored, or inadequate," said Rosemarie Ohar, OSHA's New Hampshire area director.

The industry giants, which mine all over the world, are reporting they achieved record earnings and higher production in 2009. Some don't break out safety performance in their results, but one of them, AngloGold Ashanti Ltd, said its lost-time injury rate improved 7 percent in the year's fourth quarter.